The Autoclave Myth

There has been a lot of hype about how autoclave cured spars are superior. Some builders have published extraordinary claims saying that their process yields masts that are much stronger than masts cured with a vacuum bag system. However, when you compare the weight, stiffness or safety history of masts produced by both methods, you can’t find any real difference. Below, GMT goes the distance to back up this statement.

Manufacturers of carbon sailboat spars use different methods to produce their products. The main variations are found in the materials, the process, and the compaction methods.

Materials

Carbon fiber which has been pre-impregnated with epoxy, commonly referred to as "pre-preg," requires a high temperature cure.

Carbon fiber which is wet out with epoxy on site and cures at room temperature.

process

Braiding onto male tool

Filament winding onto male tool

Bladder molding in female tool

Laying tape onto male or female tool

compaction

Vacuum bagging

Vacuum bagging plus autoclave

Bladder molding

the facts

This discussion focuses on processes where laminates are made by laying pre-preg unidirectional tape onto male or female tools, comparing laminates where the final compaction is made under vacuum at one atmosphere with laminates that are cured at 5 atmospheres.

GMT Composites has been a pioneer in the use of carbon composites in the marine industry since 1984. GMT was the first company to design and manufacture carbon spars for large cruising boats. Our masts have been used and abused since 1991. They have been on boats raced single handed around the world. They have been on cruising boats that have been rolled 120 degrees in Drake’s Passage near Antarctica. During this time, GMT spars have the best safety record in the industry due to our extensive knowledge of composites, engineering and manufacturing technique.

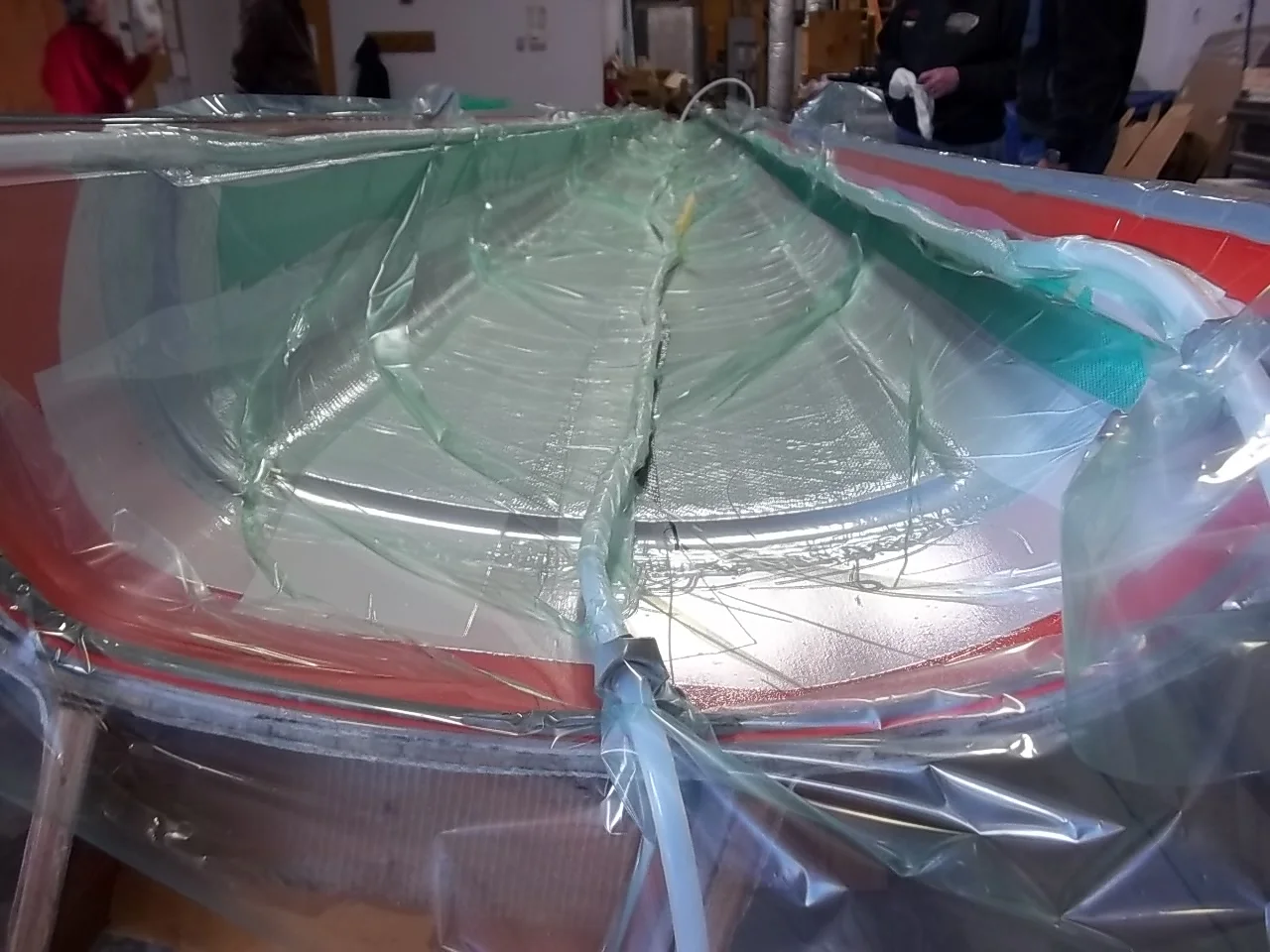

GMT manufactures spars by applying uni-directional, pre-pregs to either a male or female tool. The pre-preg material that we use is manufactured by Newport Composites. After evaluating materials from 7 manufacturers, we selected this material in 1990. Over the years, we have evaluated new resin systems, but find that the Newport product still yields superior laminates. The resin system in the pre-preg is specially designed and manufactured for a vacuum bag cure at 250F. This means that the viscosity profile with temperature and cure rate was designed so that the resin would exhibit excellent flow and fiber wet out under one atmosphere prior to curing. The result is a uniform laminate with very low void content.

Good results also depend on laying down the carbon properly. The plies must be applied smoothly in the correct orientation. Fibers must be kept straight as no amount of compacting pressure will straighten out poorly aligned fibers. In addition, the best compaction and curing schedules must be developed. Debulking under full vacuum is carried out at numerous times during the laminating process. Tape wrapping is added in select areas to aid uniformity and compaction. A similar process is carried out for the final cure. At this time, the temperature of the part is ramped up to an elevated temperature in our instrumented oven. The part is allowed to dwell at this temperature for a number of hours. This allows the softened resin to flow and the laminate to compact. After the dwell, the oven temperature is raised to the cure temperature. The resin viscosity decreases further and completely wets out the fiber. Final resin content of the part is controlled by a perforated film which allows a small amount of excess resin to flow out of the part as it compacts and cures. This flow helps remove any gases that may be in the laminate.

GMT perfected this process early on in its history. It is a process that was originally developed in the aerospace industry. It was used to make many parts from carbon-epoxy that were cured at 250 degrees. As the defense industry expanded their use of composite parts, they found that they needed laminates that would stand up better in what they call a "hot-wet environment." This is an environment where liquids such as jet fuel or exhaust at temperatures exceeding 180 degrees come into contact with the composite. A 250 degree cure epoxy laminate loses too much of its strength under prolonged exposure to these conditions. The aerospace industry was forced to switch to 350 degree cure systems using epoxy, bismaleimide or other resin systems. These resin systems are much higher in viscosity than the 250 degree cure epoxies. To increase the resin flow, manufacturers were forced to use autoclaves (for the 350 degree cure) to help squeeze the resin into the fiber and eliminate voids. This switch created its own set of problems. Increased cost, leaks from vacuum bags, and thin laminate in the corners are just some of the new areas of concern.

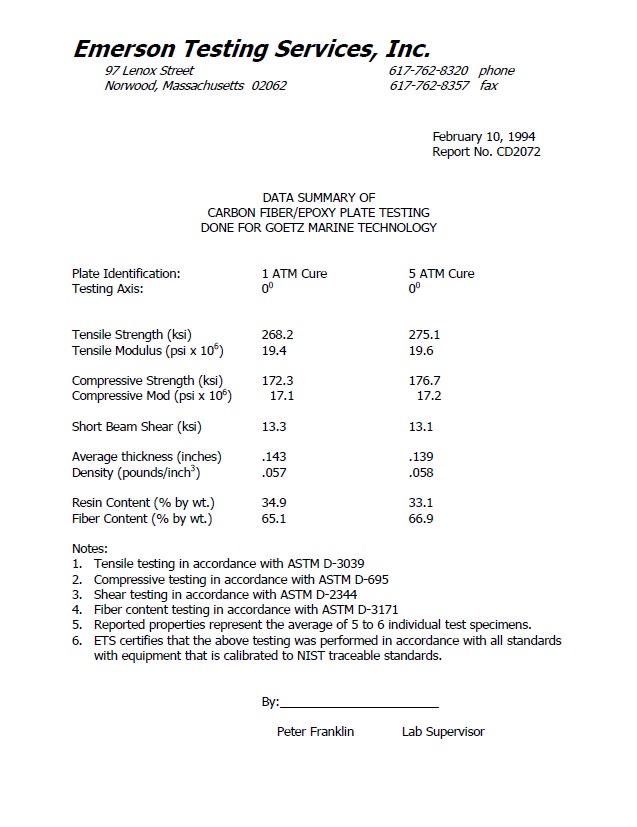

GMT has investigated the benefits of using autoclave compaction and found them to be minimal. We started this investigation back in 1993 with the help of aerospace companies who made parts by both vacuum bagging and autoclaving. Flat panels were made from the same number of plies of the same pre-preg. They were compacted using both processes. These actual panels were then tested. It is important to note that these panels were as thick as the walls in a typical mast. Data sheets published by material suppliers often show much higher results. This is because they make very thin plates under very controlled conditions so that the properties come out looking artificially high. In real life, these ideal numbers can’t be achieved. A number of spectacular failures can be attributed to builders who used data sheet numbers rather than testing composites that their shop had produced.

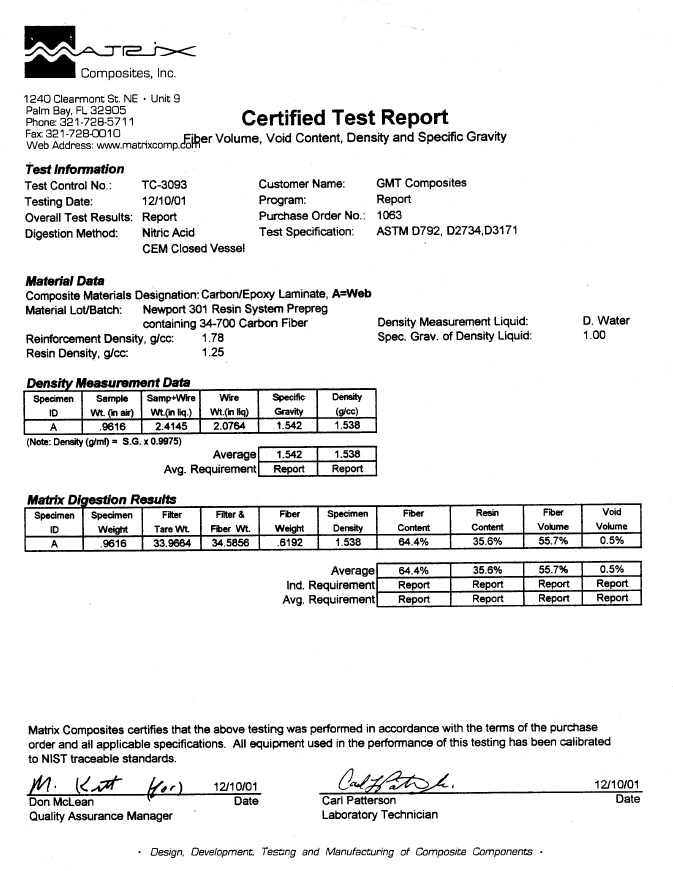

A typical test result is shown below in the report from Emerson. The autoclaved part has a bit lower resin content. It is thinner. Mechanical properties are about the same. The autoclaved part is less than 3% stronger and stiffer in tension and compression prior to taking wall thickness into account, while the vacuum bagged part is better in shear. The other test report found below is from Matrix and was done specifically to test for void content. The void content of the vacuum bagged part is very low, ½ % in this case. Although we have never void tested an autoclaved part, published reports for autoclaved parts are in the ¼ to 1% range. The test report from Matrix is from a sample cut from a 1 ½” thick stemhead we manufactured for a 154’ ketch. This is an extremely thick laminate where voids would typically be higher than in the thinner laminates seen in spars.

These small differences in properties are insignificant when it comes to the structural integrity of a mast. The main design parameter for a mast is the compressive stiffness of the column. This is because a mast will fail globally by buckling under the compressive loads from the rigging. Resistance to buckling is proportional to stiffness, E (compressive modulus) x I (moment of inertia). The compressive modulus of an autoclaved laminate is 1 to 3% higher than for a vacuum bagged laminate. However, for a given weight of laminate, the wall thickness is lower resulting in a lower moment of inertia. When the higher E is multiplied by the lower I, the resulting overall mast stiffness from quality laminates manufactured by either method is essentially the same.

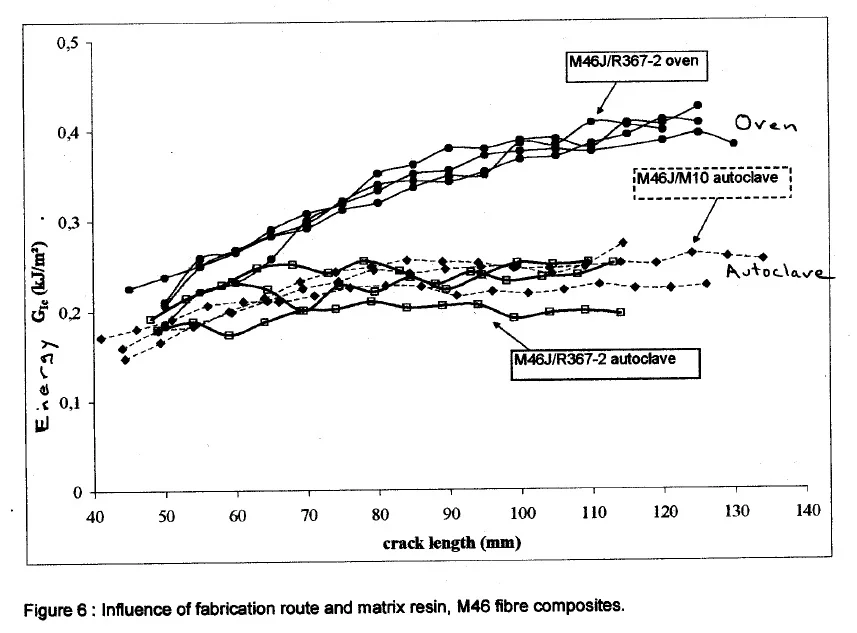

Masts can not only fail from global buckling but also from local failure of the tube. Impacts can cause delamination that may lead to failure. Recent scientific studies have shown that autoclave produced parts are more subject to delamination than oven cured. One of these studies cited below was done by Baral, Davies, Baley and Bigourdan; a group from French Universities and Industry. The work was done for the Groupama 110’ trimaran project as they investigated the material to use in their huge mast. It was published in Composites Science and Technology, March 2008. This group had samples made from five different batches of carbon that had previously been used to build masts. The samples were actually made by the mast builder. One batch was made in their autoclave and the other in their oven using a vacuum bag. A conclusion of this study is that, “Oven manufacture results in more delamination-resistant composites than autoclave fabrication.” Figure 6 from the study, also cited below, clearly shows that it takes more energy to produce a crack of a given length in an oven cured part. The authors feel this is due to the fact that vacuum bagged parts have a less distinct crack plane. “This makes fiber bridging easier as the crack plane is not flat.” They then conclude that, “This is an important observation for damage tolerance of this type of structure.” References 3, 4 and 5 from the same study also show that vacuum bagged parts are superior.

Local failures are often traceable to splices between tube sections or to changes in wall thickness in the perimeter. Most masts are built from two or more tube sections as the length of the tool or oven/autoclave limits the length of a section. GMT splices sections together by using a pre-preg scarf splice. This splice is constructed and cured using the same techniques that were used to build the sections. The result is a joint that is the same stiffness and strength as the rest of the mast. No hard spots or stress concentrations are produced with this type of splice. Manufacturers who autoclave their tube sections can not construct the splice in the autoclave. They can either use a vacuum bag cured scarf splice or a sleeve splice. Either will work well if properly engineered. However, when a splice like this is used in an autoclaved part, the argument that autoclaves must be used to produce superior masts is shown to be spurious. A second area of concern with autoclaved parts is that the corners of the section can be thinned out. As compacting pressure is applied through the bag, it tends to be concentrated at any corner. The higher the pressure the greater the chance that the fibers will be pushed away from the corners during cure, which can and has been a problem for autoclaved parts.

It is interesting that even aerospace companies are moving away from the autoclave. An article published in Composites World, June 2009, reported on some work being done by Boeing and Bristol Aerospace. They were using currently available pre-preg materials to make aerospace grade parts. Here is what the participants said, “The goal of the project was to demonstrate that an out-of-autoclave process could be used to fabricate components that would satisfy the strict requirements for aerospace grade parts.” "Our first attempt to produce a generic part using an out-of-autoclave manufacturing process proved to be a great success," said Shawna Boyko, project manager and composites engineering technical specialist at Bristol. "Inspection and coupon testing of the demonstration article showed good compaction and virtually no voids, exceeding typical quality requirements by a fair margin." Nice to see that after twenty years, the aerospace industry is now trying to catch up to the leaders in the marine industry.

Comparing test data also shows that any differences are trivial. Out of autoclave and autoclave curing are two different ways to get to the same result: a void free, properly cured spar that will perform as intended for its designed usage. Once you separate the facts from the fiction, it is clear that a high quality mast can be built by either method. All it takes is a company that knows what they are doing and the proper raw materials designed for the chosen process. GMT has proven over the past 25 years through its track record of building long lasting, quality composite structures that the GMT product is one of the finest in the marine industry.